1m semi-anechoic chamber

SAC-1 is a semi-anechoic chamber designed according to the 1m test distance, which is mainly composed of a 1m main anechoic chamber, an operation control room and a power amplifier room (conduction test chamber can be configured), which is used for the radiated immunity test and the conformity test of radiated emissions at a distance of 1m. The complete chamber system can cover CISPR, EN, FCC, GB, GJB and other standards. It can be widely used in IT products, household appliances, medical equipment, auto parts, small military electronics, industrial electronics, communications and other electromagnetic compatibility tests. After adding special interfaces, special products can be tested, such as water meters, gas meters, electric energy meters, etc.

Reference configuration

? Typical shield inner dimensions: 8m (length), × 6m (width), × 4m (height).

? Shielding structure: Smart Shield Twin Wall double-layer shielding structure, from the inside to the outside is high-performance composite conical absorber, ferrite, anti-corrosion multi-layer board, shielding steel plate, between two adjacent standard shielding modules with conductive shielding liner Gasket for good RF shielding and electrical contact connection.

? Standard shielding module: 3m ×1m in size, made of 2mm thick double-sided hot-dip galvanized steel sheet with two bends on four sides. The thickness of the double-sided hot-dip galvanized steel sheet is ≥2mm, and the thickness of the galvanized layer is ≥20μm, and the thickness is uniform. The modules are connected by M10 screws with a high strength mark of 8 or more.

? Absorbing structure: The wall absorbing material is composed of low-frequency absorbing material ferrite (100mm×100mm×6.7mm) composed of nickel-zinc-iron-manganese and high-performance EPP absorbing material (can be selected according to needs); Ground movable absorbers are composed of EPP absorbers and ferrite. The wall absorber can be covered with white reflectors to beautify the interior environment and increase brightness.

? Screen door: 0.9m×2m or 1.2m×2m or larger size can be selected, and special size design can also be carried out according to needs, the type is manual, semi-automatic and fully automatic track;

? Waveguide window: 600mm×600mm (with flange), up to 40GHz, can be selected according to needs;

? Raised floor: the load is 3 tons/㎡ as the heavy-duty area, and the other areas are 1 ton/㎡, and the height is generally 50cm;

? Filter: 380V, 220V, 110V, DC, etc., as well as network, communication and other signal filters;

? Video system: 2 sets of digital color monitoring system, one set of which is fixed on the wall and 1 set of movable floor;

? Voice system: ensure that the communication between the main dark room and the control room can be unimpeded;

? Fire alarm system: adopts high-sensitivity air sampling and analysis system, which complies with the relevant regulations of the Ministry of Public Security of China on fire prevention products;

? Lighting system: halogen lighting, 1m high from the ground illumination value of 250Lux, can be lifted;

? Lifting platform: It is convenient for large objects to enter and exit the chamber, and the automatic lifting platform is customized according to the size of the chamber door;

? Cooling air system: for the normal testing of vehicles or other high-temperature products, provide a cold air strong transmission system;

Key features

? Radiated immunity test: meets the requirements of IEC/EN 61000-4-3, ISO11452, CISPR25 and other standards.

? Radiated emission test: Meets the requirements of EN 50022, EN 50147-2, GJB 151A and GJB 152A.

? Shielding Effectiveness: Meets standard EN50147-1, GJB12190 or better.

? Long-line method: meets the requirements of CISPR25 standards.

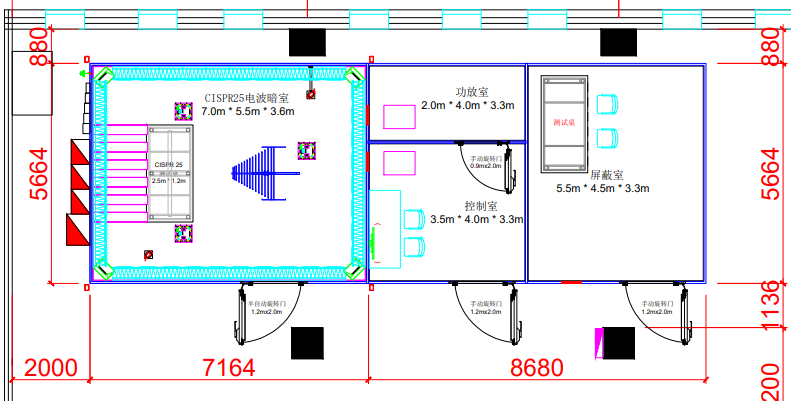

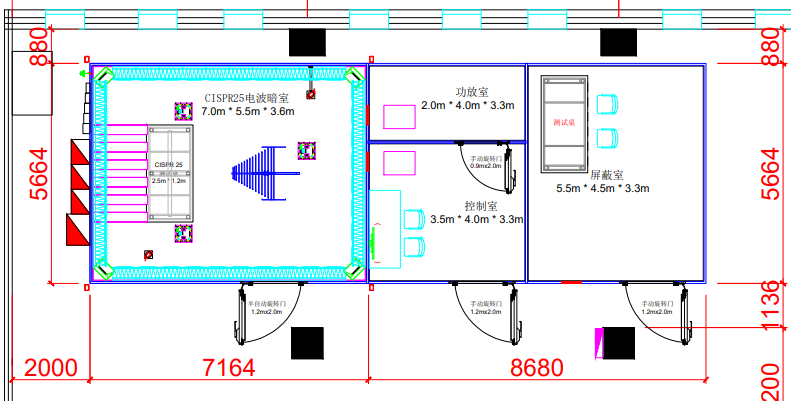

<span style="color:#333333;font-family:"font-size:14px;white-space:normal;background-color:#FFFFFF;"> the overall absorbing material layout of the anechoic chamber is shown below: